Braking overview

The standard system is of the diagonally split, dual circuit servo assisted type. Front brakes feature 240mm diameter 20mm wide vented discs, while the rear has 203mm drum brakes. The split line system is a safety feature intended to retain some braking ability should a defective part cause one of the circuits to fail.

The vacuum assisted master cylinder is situated on the left hand side of the bulkhead and is operated by a link bar to the pedal box on the right hand side. Brake pressure control vales are screwed into the two rear outlets of the master cylinder to limit braking force to 30% at the rear wheels, preventing disastrous rear wheel lock under enthusiastic braking.

The front Calipers are a variant of the standard Ford M16 type, operated by single sliding pistons. They are mounted to the front hubs.

The rear drums are actuated by twin piston wheel cylinders, and the leading shoe in each drum has a thicker lining so each shoe wears proportionally. The shoes also feature an automatic, wear compensating, adjustment mechanism.

Brake lines are 'Kunifer' plated copper from master cylinder to a point around 500mm above each braking unit. From this point flexible rubber hoses are used - all fittings are Zinc plated steel utilising M10x1 threads.

Planned modifications

I want to modify the braking system to improve its performance. There are many modifications available ranging from cheap 'big disc' conversions to amazing AP racing 4 pot calipers, brackets and huge discs with alloy bells. I want to keep the cost of this project to a sensible level, so I decided to look at other Ford cars to see how they stop!

I was wondering around my local scrap yard one day for a new dashboard, I noticed a smashed 1993 Escort RS2000. This was perfect - the front discs were significantly larger and even used the exact mounting points as the Fiesta. A huge bonus was that it had rear discs too - if I could convert them to fit my Fiesta I would be the only one I know of with this modification, on top of the engine swap. (at the time)

It's been a few years since I wrote this page, and the brakes on my cars have come a long way since the initial RS2000 conversion. The photo shows 3 stages of brakes, ranging from the 300mm single piston ST170 setup, through the 330mm 4 piston Focus RS to the awesome 360mm 6 piston Porsche Cayenne setup on my S4.

Assistance

The standard mk3,and mk3.5 brake master cylinder is a very small affair, a very old design it even saw service in the last of the mk2 XR2's. I didn't rate the braking at all on my car, the brakes lack feel and don't bite well at all - to overcome this I installed a larger servo unit.

Brake lines

I originally intended to replace just the flexible part of the hoses with stainless steel braided TFE hose, and replace the Kunifer lines with stainless steel solid lines. I could not manage to track down anyone supplying stainless solid lines, only the copper variant - which I didn't want.

In the end I settled for a single piece braided line from master cylinder to each wheel, a lot more expensive but gives better performance than standard for two reasons. Firstly the PTE braided hose has better heat radiating properties than standard, so the brakes will run marginally cooler, and secondly the lines do not expand under pressure like standard - meaning more power is sent to the brakes.

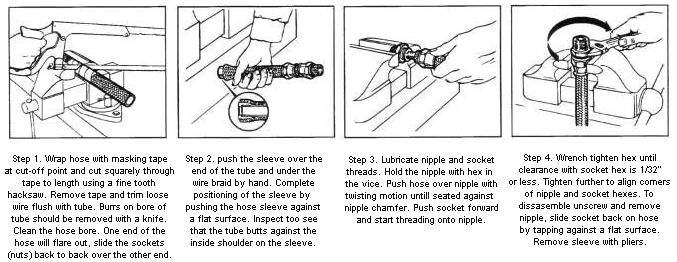

The hose I used is -3 stainless braided, TFE inner, coupled to Zinc plated fittings. To install I measured the line lengths with a piece of string, allowing a little extra for contraction (a property of this hose under pressure). To cut the hose use a fine toothed hacksaw. The fittings attach as follows:

I decided to take a different route to the standard Ford routes at the rear. Ford takes the solid line to inside the wheel arch and then a flexible line downwards into the drums (allowing for wheel movement). I found it neater to run the hose along the rear beam (allowing for movement under suspension travel) next to the handbrake cable. I fitted the hose to the beam with Earls anodised -3 hose clamps, I purchased a tap so I could secure them to the beam with countersunk Allen cap machine screws. They are expensive at over £5 each but worth it for a professional installation, I also grouped the lines together at the master cylinder with Earls tubing separators:

The above photos show the line clamps & seperators that I used to organise & secure the TFE lines to the chassis. The centre photo shows the TFE lines at the master cylinder. All braking lines and connections used were obtained from Think Automotive. separators.

© Mark Stewart, Tuesday 15th June 1999

![[XML RSS Feed]](/images/xml/xml_rss.jpg)